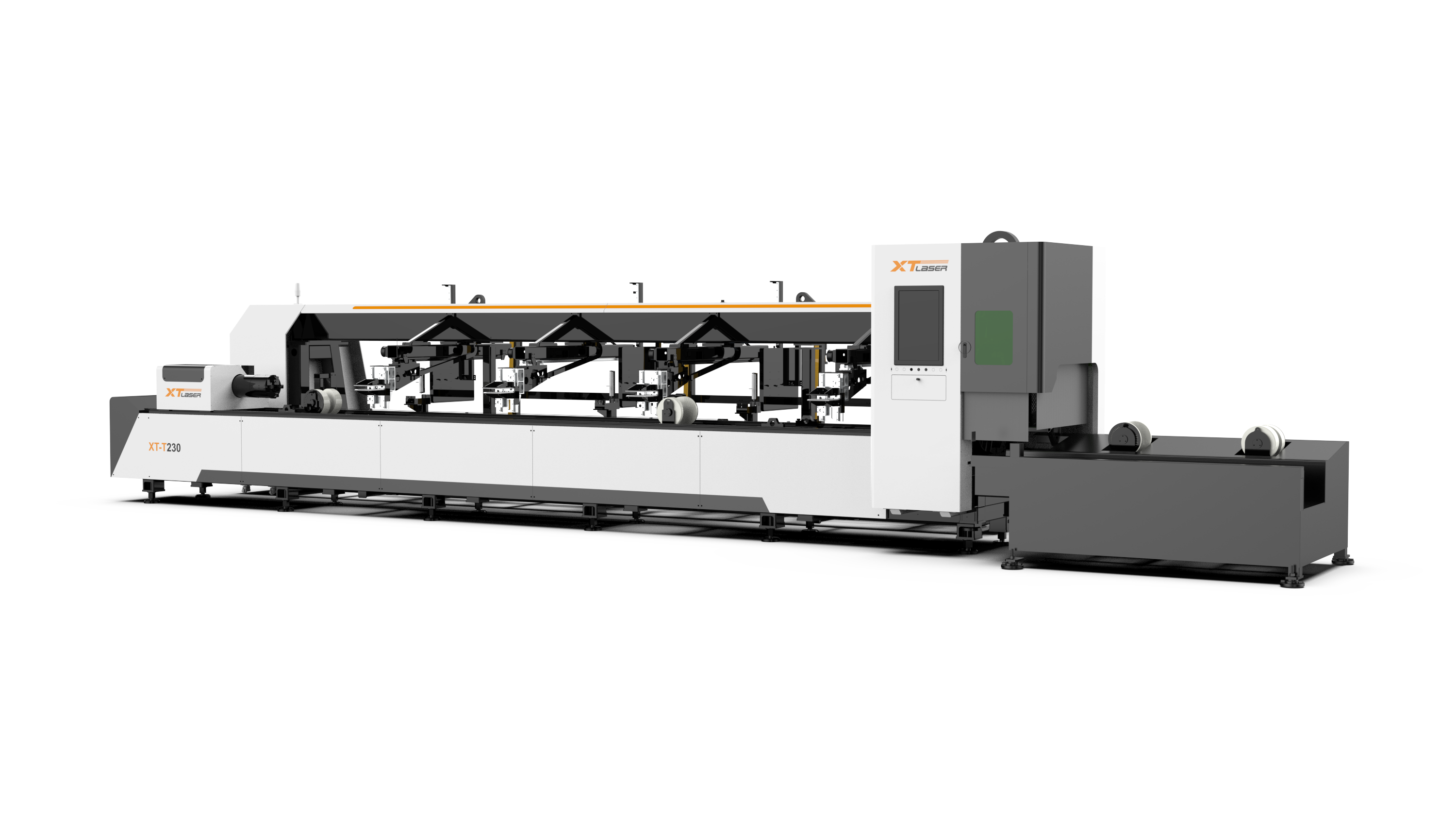

Laser cutting is one of the most popular and technologically advanced methods of processing sheet materials. The technology is characterised by the highest precision, productivity and quality, which makes it an indispensable part of the production process in many industries. Laser cutting is performed by means of special equipment which is called laser cutting machines. The modern market offers several types of such machines, each of which has its own advantages.

Laser cutting advantages

High quality characteristics of laser machines find their application in auto-, ship-, aircraft engineering, metallurgy and construction industry. Laser cutting technology is used in manufacturing of electrical and home appliances, lifts, sea containers, advertising and construction metal constructions, etc.

In comparison with existing methods of metal processing the laser has an impressive list of advantages.

clean cut - products do not need any further processing, they can be directly welded or painted;

precision - the diameter of the beam is so small that it is possible to make through holes of the same diameter as the material thickness;

high productivity - the laser cutting speed may reach up to 50 m/m

minimum waste and lower material contamination due to non-contact technological process

quality of the produced material - the machine is controlled by the program which minimizes the risk of defectiveness, guaranteeing a complete identity of the serial production;

Low consumable costs.

With a laser machine you can make products with any complex outline. And all this with minimum costs and almost total automation of the process.

- {{ words.title }}